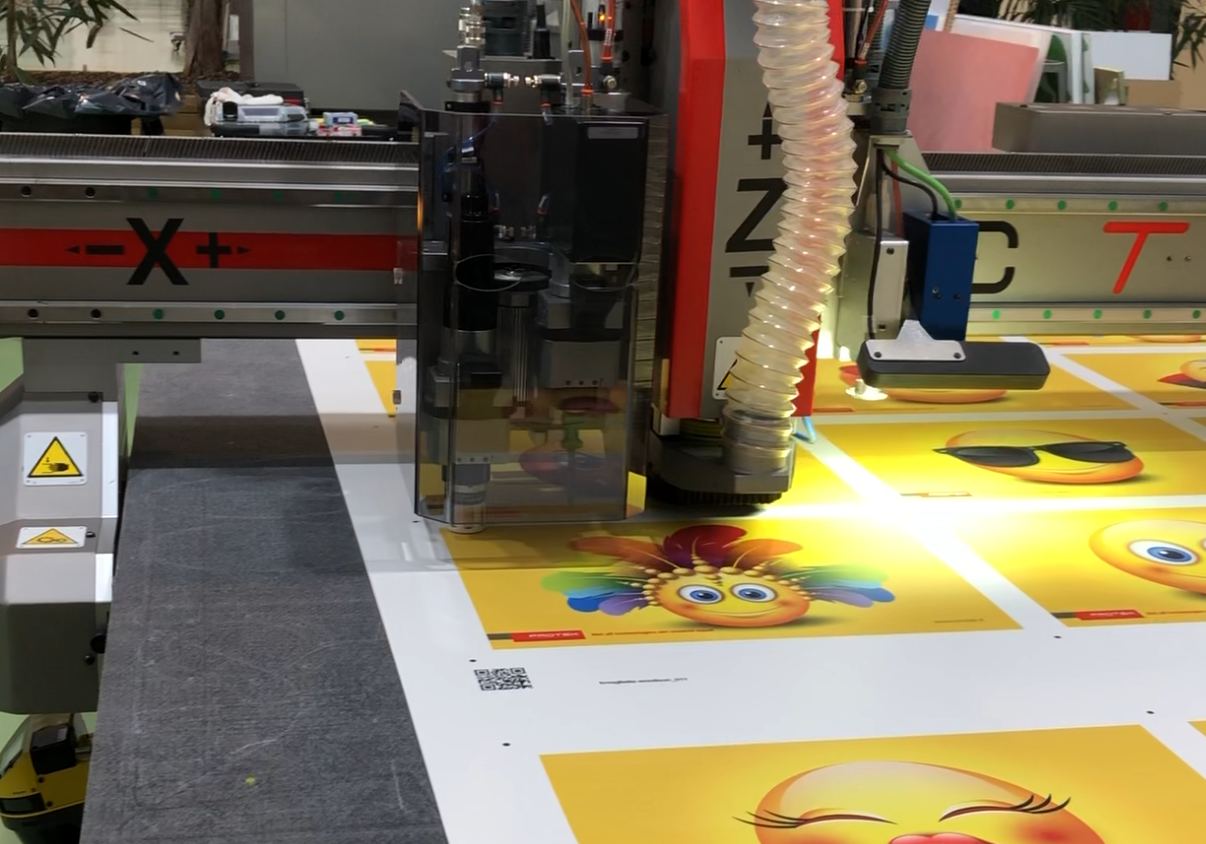

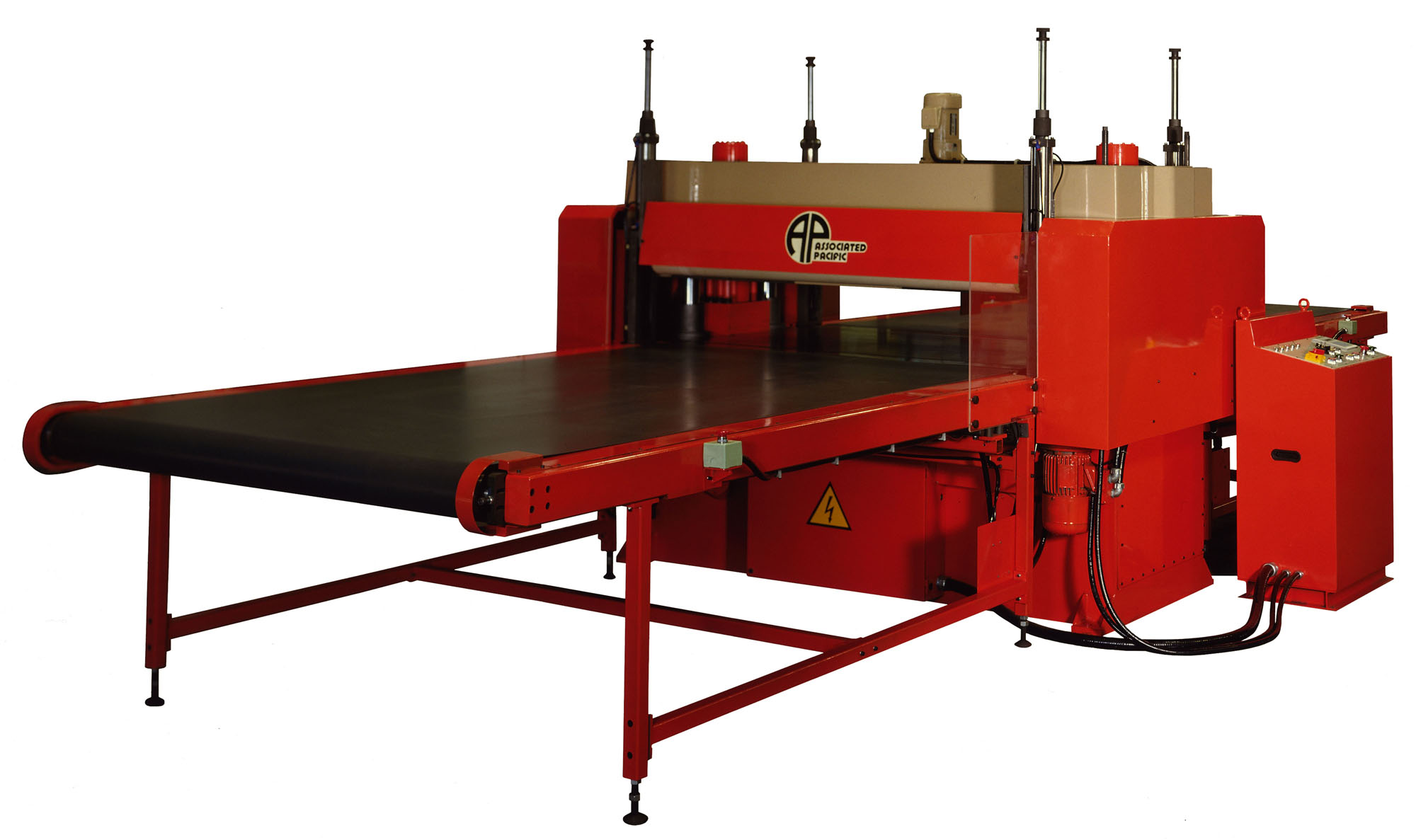

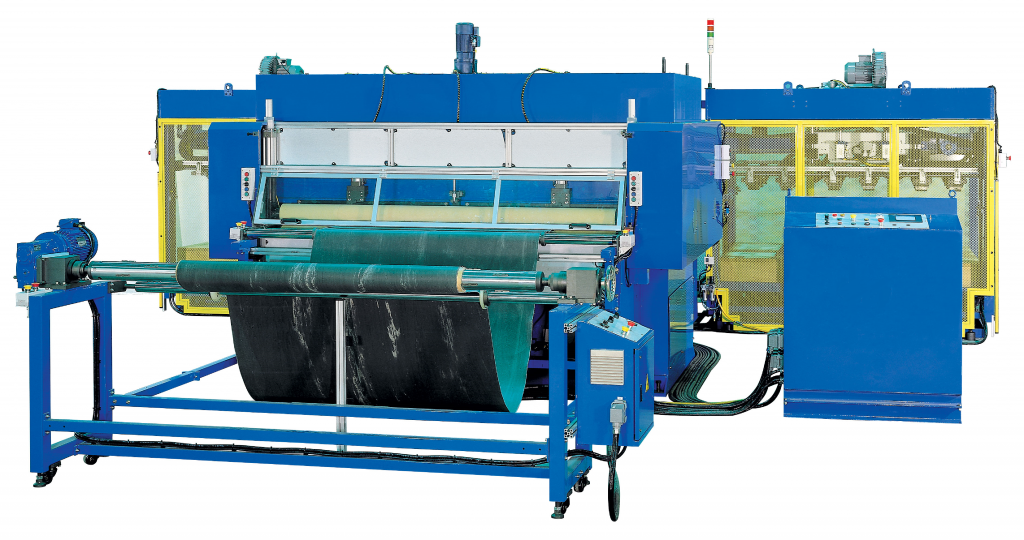

Associated Pacific Machine Corp. offers multiple machines (both die cutting and CNC) for cut-to-print applications in the graphics industry. Our newest machine with cut-to-print capability is the Protek Unico TT – using the onboard camera and a CNC knife or router, the Unico TT can cut even very sophisticated custom shapes from a wide range of materials. Here’s a quick look at the machine in action:

Learn more about the machine here: https://apmcorp.com/product/unico-tt/