Products

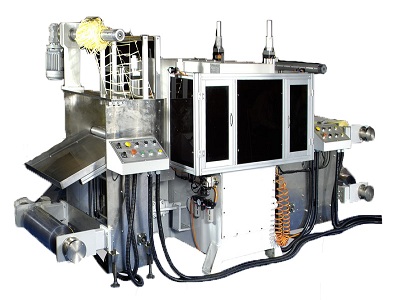

Roll Material Precision Hydraulic Cutting Machine (KR-40)

Description

This machine is designed for continuous work for through cutting and kiss cutting of roll materials, suitable for electronics field, packing industry, etc.

Features

Features

- Manual 4 post mechanical stops accuracy +/- 0.02mm with micro adjustment, adjustment accuracy 0.01mm, can do kiss cutting

- Touch screen operator interface and accessories can save 300 sets cut program

- HRC60° hardened and ground steel plate, ensure perfect cutting edge.

- Servo motor positioning of the roll feeder, position accuracy of +/- 0.1mm

- 75 cuts per minute, based on 20mm cutting stroke and a 10mm feeding distance

- Adjustable die rails

- Circle PET belt feeding system

- Waste Rewind and finished rewind

- Safety guard and safety photocell

Options

Specifications

| Cutting Force: | 44 tons (40 Metric tons) |

| Maximum Daylight: | 5.12" (130mm) |

| Machine Bed: | 23.6" x 23.6" (600 x 600mm) |

| Main Motor: | 5 HP |

| Gross Weight: | 6160 lBS (2800 Kgs) |

| Series: | KR-40 |